© Shipping Wonders of the World 2012-

Dredgers and Hoppers

The entrances to many ports must be kept free from silt, and without the ugly but efficient dredgers and hoppers that keep the channels clear even the greatest ports might fall into disuse

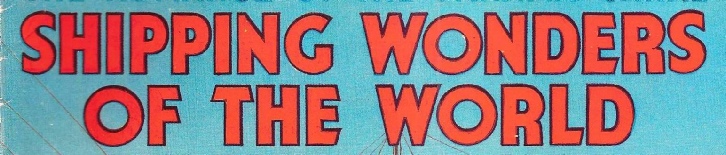

IN THE HEART OF LONDON opposite the Houses of Parliament, a grab dredger is seen in the photograph on the left. This vessel, the Port of London Authority Dredger No. 8, flies a large flag to show that dredging operations are in progress. The existence of the Port of London is dependent on the activities of its dredgers.

IN THE HEART OF LONDON opposite the Houses of Parliament, a grab dredger is seen in the photograph on the left. This vessel, the Port of London Authority Dredger No. 8, flies a large flag to show that dredging operations are in progress. The existence of the Port of London is dependent on the activities of its dredgers.

A DREDGING OUTPUT of 750 tons an hour is given by the bow well self-

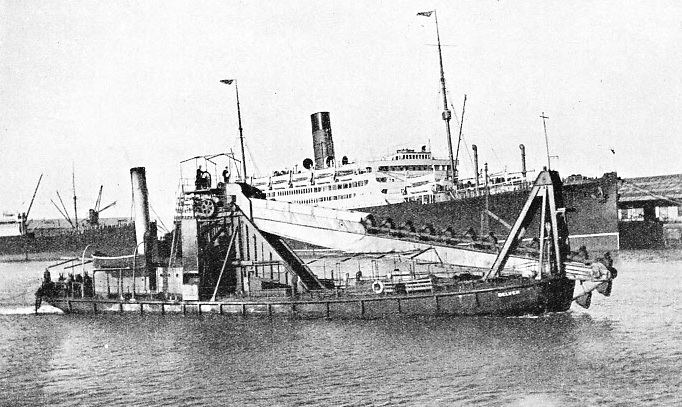

AN INDIAN SUCTION HOPPER DREDGER, the Balari, is seen in the lower photograph at work on one of the many bars in the river Hooghly, below Calcutta. The bed of this great river is constantly shifting and, although dredgers are always busy, a special service of pilots is necessary to keep pace with the continual altering of the navigable channels. The Hooghly is the western arm of the delta of the River Ganges and flows into the Bay of Bengal.

THERE is a type of vessel so ungainly in appearance that it has been called the ugly duckling of the shipbuilder’s family. This type is the dredger. Appearance, however, is not everything, and the dredger is essential to the prosperity -

Navigable channels liable to be choked by deposits of silt have to be continually dredged, or they will become useless. In some instances a river is so completely cleared by human agency that its character is changed. The classical example is the River Clyde, birthplace of so many fine vessels, including the RMS Queen Mary.

In days gone by, the Clyde resembled other Scottish rivers; it had a rapid flow from source to mouth, and comparatively little depth even at Glasgow. It was a good trout and salmon stream, but of little apparent use to anyone who might propose to make Glasgow one of the great ports of the world. Were the Clyde in its original state to-

The Clydeside shipping industry owes its existence to the dredging of the river, and the continuance of that industry is made possible only by dredging, incessantly repeated.

What is true of the Clyde is true elsewhere. In the Netherlands, the muddy mouths of the Rivers Maas and the Waal have to be subjected to constant dredging to keep them clear for navigation.

Without this labour the great seaport town of Rotterdam and her lesser sister Dordrecht might well sink to the insignificance of the “Dead Cities” of the Zuider Zee. Only a little farther south, exactly the same thing happens with busy Antwerp on the muddy River Schelde.

In England, on the Thames, the Mersey, the Humber or the Tyne, the dredgers are busy keeping the fairways open. Some idea of the dredging out of the Tyne will be gathered from an interesting fact. When the famous High Level Bridge at Newcastle-

A dredge, in its simplest form, is nothing more than a shovel or scoop. A single shovel, even a giant power-

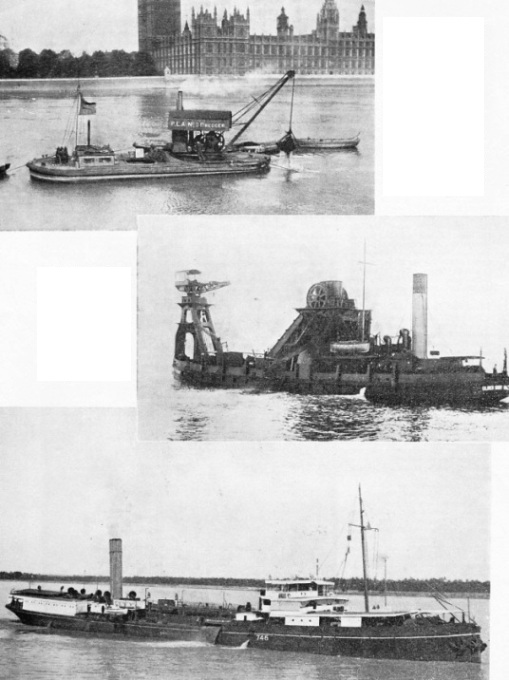

THE FIRST STEAM-

The bucket dredger is no longer alone in the field of modern dredging, for the suction dredger also is extensively used nowadays. The bucket dredger, however, holds its own for certain types of dredging, as a soft river or canal bed is necessary for the successful working of the suction dredger.

The forerunner of the bucket dredger was the “bag and spoon” apparatus, which dates back to the latter part of the sixteenth century, if not earlier. For river clearance, this consisted of a perforated leather or network bag, mounted on a ring at the end of a long pole or beam, resembling in its general principle a giant shrimping net. The beam in its turn was mounted on a fulcrum at its centre, in the same way as the beam of an old-

An old Dutch print, dated 1565, shows this early form of dredger employed in the removal of a mudbank. The dredger had the beam and fulcrum and was worked by three men. The boat was propelled by an enormous single oar in the stern, and was held steady during operations by four stout anchor cables. The “bag-

In the second decade of the seventeenth century a notable advance was made with the introduction of a grab-

Netherlands Origin

The immediate precursor of the modern bucket dredger was the Dutch mud dredger. This was probably invented by J. J. Nieng, who was Burgomaster of the town of Hoorn in 1632. Adam Clippens of Ghent, a contemporary of Nieng, has also been claimed as the inventor. With the then incessant trouble arising through the silting up of muddy rivers in the Low Countries, it is not impossible that the mud dredger was invented independently and almost simultaneously by these two men.

The early mud dredger involved the use of a series of flat paddles operating on an endless belt which was worked through a system of gears by a large capstan on board the dredging vessel. The capstan in its turn was worked by either horses or men, according to the size of the dredger.

The belt ran over a rigid frame that was let down into the bed of the river by a derrick, and the up-

Although the mud dredger answered its purpose well enough in waters where the bottom consisted of soft mud or even flaky clay, it was almost useless for shingle or for a coarse gravelly bed.

SELF-

From the mud dredger with paddles to the bucket dredger was but a short step. In the modern dredger the old paddles are replaced by strong iron buckets, working in a contrary direction to that of the paddles on the old mud-

The modern bucket dredger, however, has many accessories and improvements never visualized by the early Dutch inventors. Powerful tackle is installed for the hoisting of the bucket frame or, as it is called, the “ladder”, up into the well of the vessel when it is not in use. The spoil is separated from the water which comes up with it in the buckets, so that the spoil can be shot into a hopper without much superfluous water, which is ejected overboard.

All the dredging equipment has to be of the strongest and most robust description. The first application of manganese steel, invented by Sir Robert Hadfield in 1882, was made in the construction of a bucket dredger for the Ribble Navigation Department of the Preston (Lancs) Corporation. The bucket chain had manganese steel pins. Fifteen months after the chain had been installed the apparatus was overhauled, and the manganese steel pins were found to be almost unworn. The ordinary pins wore out after about four months of service. A typical modern dredger may be driven by a 200 hp triple-

A typical sea-

There are many variations of the suction dredger. Soft spoil is sucked up by a power-

The Bazin sand pump was used for some time in the dredging of the Suez Canal, and was claimed to be capable, when working from a depth of approximately two fathoms, of dealing with 3,000 cubic metres (over 3,920 cubic yards) of sand a day. The first automatic-

Spoil may be tipped either into the vessel’s own hopper or into a special hopper barge lying alongside. In the hopper the bottom opens and is pressed to again by the water as soon as the spoil has dropped.

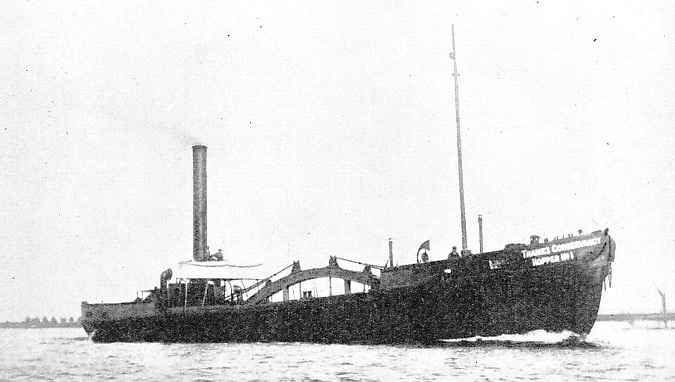

IN DRY DOCK AT TILBURY, Essex, the Port of London Authority Hopper No. 5 is refitting. In the background is the P. and O. liner Narkunda, 16,632 tons gross, also in dry dock. The Port of London Authority hoppers carry mud dredged from the bottom of the London River -

Another useful though scarcely beautiful type is the London County Council sludge vessel, indispensable to the health of the capital. The great sewer outfalls at Barking and Crossness -

A vessel of this class may have a gross tonnage of over 1,500, and be capable of carrying 1,000 tons of sludge in four huge, rectangular tanks. Well out to sea, special valves are opened and the unwanted cargo of these vessels is rapidly discharged into the water, about ten feet below the surface. It is quickly diffused by the action of the ship's propellers, the whole operation taking only a few minutes.

So we cannot look at the ugly sanitary vessel, or at the ungainly hopper or bucket dredger, without feelings of real respect. On the one depends the health of the city, and on the other two the activity of the seaport, and even its existence.

You can read more on “Bow Well Bucket Dredger” and “The Fulham” on this website.

You can read more on “Dredgers at Work” in Wonders of World Engineering